NEWS CENTER

The chemical differences between the Monel, Inconel, Incoloy and Hastelloy grades

2022-10-21

The role of different elements in nickel alloys

Nickel alloys are the most widely used and strongest superalloys. Nickel in nickel alloys is an austenite stabilizing

element that enables nickel alloys to maintain the FCC structure, so that more other alloying elements can be dissolved,

while maintaining good structural stability and material plasticity.

Cr, Mo, Al play the role of anti-oxidation and anti-corrosion, and have a certain strengthening effect.

The action modes of nickel alloy strengthening elements can be divided into the following three types:

1. Solid solution strengthening elements

Due to the different atomic radii from basic atoms, solid solution strengthening elements (such as W, Mo, Co, Cr, V, etc.) can form local lattice strain in the Ni-Fe structure to achieve the effect of strengthening the material.

2. Precipitation-enhancing elements

Precipitation strengthening elements such as Al, Ti, Nb, Ta, etc., can form an overall ordered A3B type intermetallic compound, such as Ni3 (Al, Ti) and other strengthening phases (γ'), so that the alloy can be effectively strengthened and obtained than iron. Higher high temperature strength of base alloys and cobalt-based alloys.

3. Grain boundary strengthening elements

Grain boundary strengthening elements, such as B, Zr, Mg, rare earth elements, etc., can improve the high temperature performance of the alloy.

Differences between Monel, Inconel, Incoloy and Hastelloy grades

Typically, grades of nickel alloys are named by the manufacturer who developed them. E.g:

Ni-Cu alloys are also known as Monel alloys, such as Monel 400 and Monel K-500.

Ni-Cr alloys are generally called Inconel alloys, such as Inconel 600 and Inconel 625, which are common heat-resistant nickel alloys. They are mainly used under oxidative media conditions.

If more iron is added to replace nickel in Inconel alloy, it will become Incoloy alloy, such as Incoloy 800, Incoloy 825, etc. They are not as high temperature resistant as precipitation hardening nickel alloys, but they are less expensive. They are used in cryogenic components of jet engines and reactors in petrochemical plants.

If precipitation strengthening elements (Ti, Al, Nb, etc.) are added to Inconel and Incoloy, it becomes a precipitation hardening nickel alloy such as Inconel 718 and Incoloy A-286, which can still maintain good mechanical strength and corrosion resistance at high temperatures. They are mainly used in jet engine components.

Ni-Cr-Mo(-W)(-Cu) alloy is called Hastelloy, in which Ni-Cr-Mo is mainly used to reduce medium corrosion. The representative grades of Hastelloy are Hastelloy C-276, C-2000 and so on.

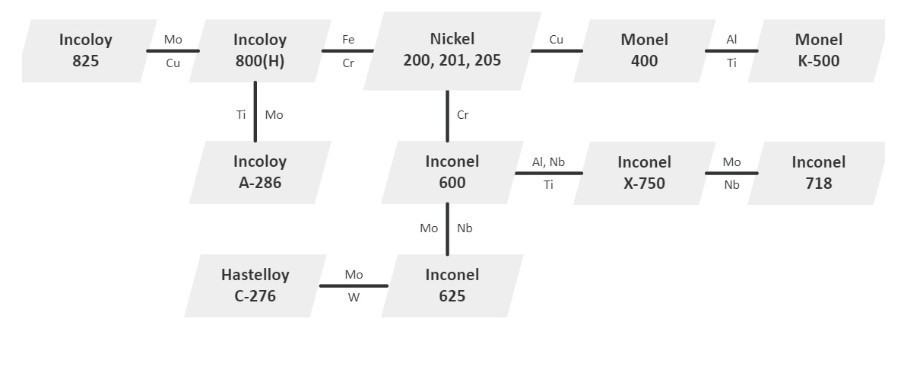

The following figure summarizes the elemental relationship between different nickel alloy grades for your reference:

Jiangsu Bohang Alloy Technology Co., Ltd.

MAIL: info@bh-alloy.com

ADD.:No. 8, Fenglin Avenue, East Park, Lvcheng Town, Danyang City, Jiangsu Province

Copyright© 2022 Jiangsu Bohang Alloy Technology Co., Ltd. Powered by www.300.cn

This website already supports IPV6 SEO